What Is a CWI Stamp and Why Is It Important in Welding?

Welding plays an essential role in various industries, from construction to manufacturing. The quality of welds is critical not only for the durability of structures but also for safety. This is where a Certified Welding Inspector (CWI) stamp comes in. But what exactly is a CWI stamp, and why is it so important?

Understanding the CWI Stamp

A CWI stamp signifies that a welding project has been inspected and approved by a Certified Welding Inspector. The American Welding Society (AWS) oversees the certification process, ensuring that those who earn the CWI title possess a deep understanding of welding processes, inspection standards, and quality assurance practices.

When a project receives a CWI stamp, it indicates that the welds have been inspected for compliance with industry standards. This stamp acts as a seal of approval, confirming that the work meets safety and quality requirements.

Why the CWI Stamp Matters

The CWI stamp is not just a formality—it’s an assurance of quality. Here’s why it holds such importance in the field of welding:

- Ensures Structural Integrity A CWI stamp guarantees that welds have been inspected for defects like cracks, porosity, and other imperfections that could compromise the structure’s strength. Without proper inspection, substandard welds may go unnoticed, leading to potential failures.

- Promotes Safety Poorly welded joints can lead to accidents, equipment failures, or even catastrophic consequences, especially in high-stakes environments like bridges, pressure vessels, and pipelines. A CWI stamp ensures that each weld is safe and reliable, minimizing risks for workers and the public.

- Compliance with Standards Industries rely on strict welding codes and standards to maintain safety and uniformity. The CWI stamp signifies that a project adheres to these regulations. This compliance is crucial for obtaining certifications, passing inspections, and avoiding legal or financial setbacks.

- Increases Trust and Credibility Companies with projects that feature a CWI stamp gain trust and credibility in the industry. Clients, contractors, and regulatory bodies value this mark because it confirms that the work has met rigorous quality checks by a certified expert.

- Reduces Long-Term Costs Addressing welding flaws early, through proper inspection, prevents costly repairs or replacements down the line. By ensuring high-quality welds upfront, the CWI stamp helps companies save money over time.

The Process of Earning a CWI Stamp

Not every inspector can provide a CWI stamp. Achieving the Certified Welding Inspector designation requires passing an exam that tests knowledge of welding fundamentals, inspection techniques, and code applications. CWIs need to stay current with training and certifications to maintain their expertise.

After a weld is completed, the inspector assesses it using various methods such as visual inspections, ultrasonic testing, or radiographic analysis. Once a weld passes the examination, the CWI applies their stamp, signifying that the weld meets all required standards. also

Importance Across Different Industries

The significance of a CWI stamp varies but is crucial across multiple fields:

- Construction: Ensures that buildings, bridges, and other infrastructure projects have strong, secure welds.

- Manufacturing: Maintains the quality of welded components used in machinery, vehicles, and equipment.

- Oil and Gas: Guarantees that pipelines and related facilities are welded safely to prevent leaks or failures.

- Aerospace: Confirms that welds in aircraft and space equipment meet stringent safety standards, given the high stakes involved.

Each of these industries relies on CWIs to verify that the work is up to code and that it will perform as needed under various stresses.

Final Thoughts

A CWI stamp represents more than just an inspector’s mark—it’s a crucial element of the welding industry that stands for safety, quality, and adherence to standards. It shows that an experienced, certified inspector has verified the work, providing peace of mind to project managers, clients, and workers. Investing in CWI-inspected welds not only enhances trust but also protects both the company and its workforce by ensuring safer, stronger structures.

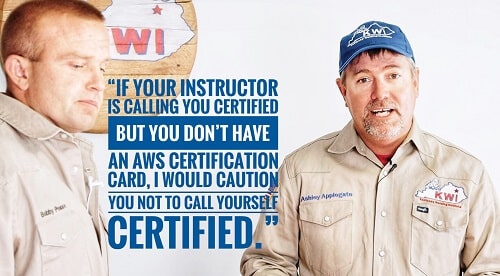

If you’re in need of professional welding inspection services or want to learn more about the benefits of having a CWI-certified inspector on your team, reach out to kentucky welding institute. Ensure your projects meet the highest standards in the industry.