Effective inventory management is the lifeline of any successful business. Whether you operate a small retail store or a large manufacturing company, managing your inventory efficiently can optimize operations, reduce costs, and improve customer satisfaction. In this article, we explore practical tips and strategies to help businesses streamline their inventory processes and achieve long-term success.

1. Understand Your Inventory Needs

The foundation of efficient inventory management lies in understanding your specific business needs. Analyzing historical sales data, seasonal trends, and demand patterns can help you determine which products are in demand and which are not. Categorizing inventory into groups, such as fast-moving, slow-moving, and obsolete, enables better resource allocation and decision-making.

Businesses that collaborate with 3PL logistics services often benefit from their expertise in analyzing and managing inventory trends, ensuring smoother supply chain operations.

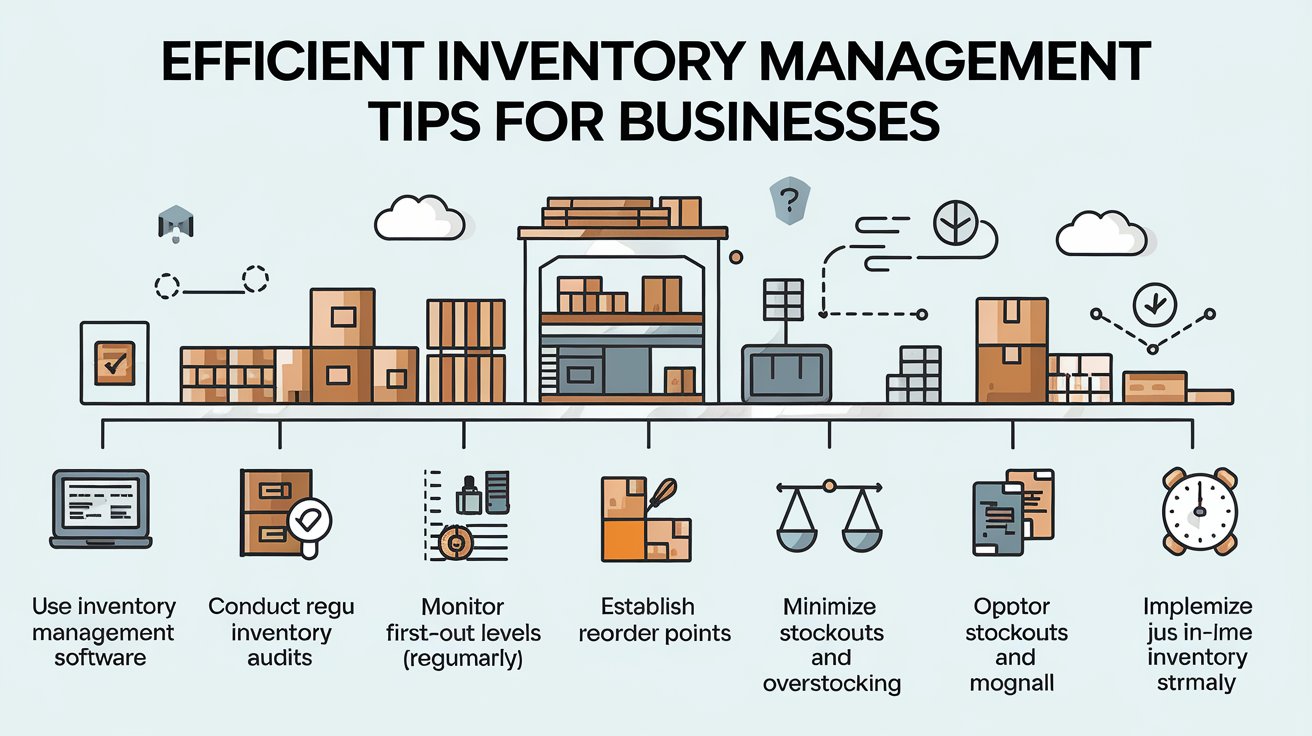

2. Adopt an Inventory Management System (IMS)

Modern inventory management systems are invaluable for tracking stock levels, orders, and deliveries in real time. A robust IMS eliminates the guesswork, offering accurate data to prevent overstocking or stockouts.

Advanced systems also integrate with accounting software and sales platforms, providing a centralized solution for inventory control. Businesses that leverage such technology can maintain optimal stock levels, improve accuracy, and reduce manual errors.

3. Implement ABC Analysis

ABC analysis is a technique that categorizes inventory based on its value and significance.

- Category A: High-value items with low sales frequency.

- Category B: Moderate-value items with average sales frequency.

- Category C: Low-value items with high sales frequency.

This method helps businesses prioritize their focus on the most critical items, ensuring they allocate resources wisely while maintaining the availability of essential products.

4. Leverage Just-in-Time (JIT) Inventory Practices

The Just-in-Time (JIT) inventory model minimizes the amount of stock held by ordering goods only when they are needed. This strategy reduces storage costs, decreases waste, and improves cash flow. However, JIT requires precise coordination with suppliers and a reliable supply chain to avoid delays.

Many businesses using 3PL logistics services successfully implement JIT practices, as these providers ensure timely deliveries and efficient inventory handling.

5. Set Minimum and Maximum Stock Levels

Defining minimum and maximum stock levels is a straightforward yet effective way to manage inventory. The minimum stock level ensures that you always have enough inventory to meet demand, while the maximum stock level prevents overstocking and excessive storage costs.

Periodic reviews of these levels based on market conditions and sales trends ensure your business remains agile and responsive to changing demands.

6. Conduct Regular Audits

Periodic inventory audits are essential for maintaining accuracy and identifying discrepancies. There are three common types of audits:

- Full inventory audits: Comprehensive checks of all inventory.

- Cycle counting: Random checks of specific inventory categories.

- Spot checks: Unscheduled inspections of high-value or fast-moving items.

Audits not only ensure that your records match actual stock but also help detect theft, damage, or inefficiencies in your processes.

7. Monitor Lead Times Closely

Understanding supplier lead times is critical for effective inventory planning. Longer lead times can result in stockouts if not managed proactively, while shorter lead times allow for greater flexibility.

Building strong relationships with suppliers and maintaining clear communication can help mitigate risks associated with unexpected delays. Additionally, consider having backup suppliers for critical inventory to avoid disruptions.

8. Invest in Employee Training

Your inventory management system is only as effective as the people using it. Training employees on inventory best practices, software tools, and standard operating procedures ensures smooth operations and reduces errors.

Encourage your staff to understand the importance of accurate data entry, timely stock updates, and efficient handling of goods to maintain overall productivity.

9. Embrace Automation and Technology

Automation has transformed inventory management by reducing human intervention and increasing efficiency. Barcoding, RFID technology, and IoT-enabled sensors are some tools that offer real-time insights into stock movement and storage conditions.

For example, temperature-sensitive goods can be monitored using IoT devices to ensure they remain within acceptable ranges, preventing spoilage or damage. Automated solutions also save time and enable faster decision-making.

10. Utilize Demand Forecasting

Demand forecasting involves analyzing historical data, market trends, and customer behavior to predict future demand. Accurate forecasting helps businesses prepare for peak seasons, avoid overstocking, and manage cash flow effectively.

Modern forecasting tools use machine learning and AI to provide more precise predictions, empowering businesses to make informed decisions about procurement and production.

11. Optimize Warehouse Layouts

An organized warehouse layout significantly impacts inventory management efficiency. Grouping similar items together, ensuring proper labeling, and placing fast-moving items closer to dispatch areas reduce picking times and improve workflow.

Investing in vertical storage solutions and adjustable shelving can maximize space utilization, especially for businesses with limited storage capacity.

12. Monitor Inventory Turnover Ratios

Inventory turnover ratio measures how quickly your stock is sold and replaced within a given period. A high turnover rate indicates efficient inventory management, while a low rate signals overstocking or slow-moving products.

Regularly reviewing this metric helps businesses identify underperforming products and adjust their strategies accordingly.

13. Streamline Returns Management

Handling returns effectively is an integral part of inventory management. A clear returns policy, coupled with efficient reverse logistics, ensures that returned goods are processed quickly and reintegrated into inventory.

Reliable inventory management systems can track returns, categorize them, and determine whether they should be restocked, repaired, or discarded.

14. Focus on Customer-Centric Inventory

Understanding customer preferences and buying patterns allows businesses to stock the right products in the right quantities. Regular surveys, feedback mechanisms, and data analysis tools help identify popular products, enabling businesses to prioritize their availability.

This approach enhances customer satisfaction while minimizing the risk of carrying obsolete inventory.

Conclusion

Efficient inventory management is vital for maintaining a balanced supply chain, improving cash flow, and meeting customer expectations. By adopting strategies like automation, demand forecasting, and periodic audits, businesses can ensure their inventory processes are streamlined and cost-effective. Collaborating with 3PL logistics services further enhances inventory efficiency, providing expert support and resources to handle complex supply chain needs.