In industries that demand high precision and safety, the helium leak detector has become a vital tool. From aerospace engineering to medical device manufacturing, this advanced technology ensures reliability and accuracy in identifying leaks. This article will guide you through the workings, applications, and benefits of helium leak detectors, tailored to the needs of those seeking efficient and effective leak detection solutions.

What Is a Helium Leak Detector?

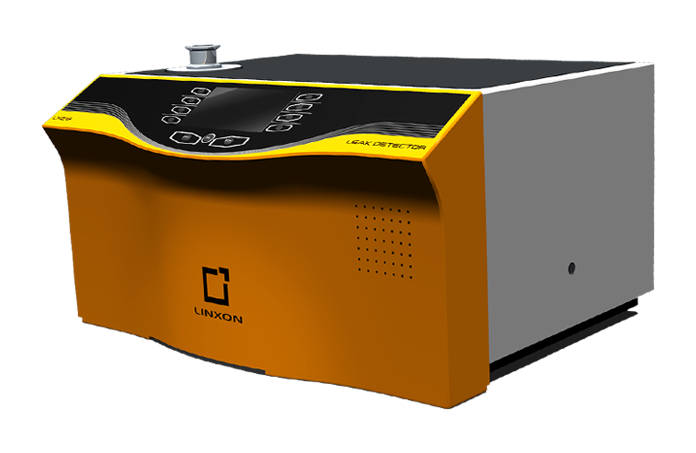

A helium leak detector is a specialized device used to locate and measure leaks in various systems and components. It relies on helium gas as a tracer due to its small molecular size and inert nature, allowing it to detect even the smallest leaks with unparalleled accuracy.

The detector operates in two main modes:

- Vacuum Mode

Used for systems under vacuum, it detects helium that enters through leaks. - Sniffer Mode

For pressurized systems, it identifies helium escaping from leaks.

Applications of Helium Leak Detectors

Helium leak detectors are employed across multiple industries, ensuring the integrity and safety of critical systems:

1. Aerospace Industry

- Ensures the safety of fuel systems, hydraulic systems, and life-support equipment.

- Detects micro-leaks that could compromise the performance of spacecraft or aircraft.

2. Automotive Sector

- Verifies the integrity of air conditioning systems, fuel tanks, and exhaust systems.

- Prevents emissions and ensures optimal vehicle performance.

3. Medical Equipment Manufacturing

- Tests the hermetic seals of devices like pacemakers and oxygen delivery systems.

- Prevents contamination and ensures patient safety.

4. Semiconductor Production

- Detects leaks in vacuum chambers and gas lines used in chip manufacturing.

- Guarantees clean and precise operating conditions.

5. Power Generation

- Inspects turbine casings, heat exchangers, and cooling systems.

- Enhances efficiency and reduces energy loss.

Benefits of Using a Helium Leak Detector

The advantages of helium leak detection extend beyond accuracy. Here’s why it stands out:

- High Sensitivity

Capable of detecting leaks as small as 10⁻⁹ mbar·L/s, ensuring precision. - Non-Reactive Nature

Helium is an inert gas, eliminating the risk of reactions with materials. - Fast and Reliable

Speeds up leak detection while maintaining consistent results. - Cost-Effective in the Long Run

Prevents costly repairs and downtime by identifying leaks early. - Environmental Safety

Reduces emissions and supports compliance with environmental standards.

Key Features to Look for in a Helium Leak Detector

When selecting a helium leak detector, consider the following factors to ensure optimal performance:

- Sensitivity Range

Choose a detector capable of identifying the smallest leaks required for your application. - Ease of Use

Opt for models with user-friendly interfaces and automated features. - Portability

Lightweight and portable detectors are ideal for on-site testing. - Durability

Ensure the detector is robust enough to withstand industrial conditions. - Data Logging Capabilities

Advanced models can record and store test data for further analysis.

How to Use a Helium Leak Detector

Proper use of a helium leak detector is crucial for accurate results. Follow these steps:

- Prepare the System

Clean the surface and isolate the area to be tested. - Introduce Helium Gas

Inject helium into the system or around the suspected leak area. - Operate the Detector

Use the sniffer or vacuum mode to detect helium escaping from the system. - Analyze Results

Evaluate the readings to locate and measure the leak. - Address the Leak

Once identified, repair the leak and retest to ensure system integrity.

Maintenance Tips for Helium Leak Detectors

To maximize the lifespan and efficiency of your helium leak detector:

- Regular Calibration

Ensure accurate readings by calibrating the device as recommended by the manufacturer. - Clean the Sensors

Remove contaminants that could affect sensitivity. - Check for Wear and Tear

Inspect components like seals and hoses for damage. - Use Pure Helium

Avoid using impure helium, as it can impact detection accuracy.

Why Helium Leak Detection Is Essential

In modern industries, even the smallest leaks can lead to significant problems, from operational inefficiencies to safety risks. The helium leak detector offers a reliable solution, providing unparalleled accuracy and speed in identifying and addressing leaks.

Final Thoughts

The helium leak detector is an indispensable tool for industries prioritizing safety, efficiency, and reliability. Its precision, coupled with its versatility across applications, makes it a critical investment for leak testing. Whether you’re in aerospace, medical manufacturing, or power generation, understanding the features and benefits of this technology will help you ensure system integrity and optimize performance.

Choose the right helium leak detector and take proactive steps to secure your operations while minimizing risks and costs.